Sustainability mindset drives action

At DuPont, we are passionate about all forms of sustainability. We are proud to lead by example—creating innovative, sustainable solutions while reducing our operational footprint and supporting the communities in which we work and live.

Continuously improving our operational footprint

We manufacture DuPont™ Tyvek® in Richmond, VA, USA, and Contern, Luxembourg, Europe. Each site has a sustainability leader who is responsible for creating plans for their site that will aid in decoupling carbon emission from growth while considering the site’s future needs.

We have achieved significant progress in reducing our greenhouse gas (GHG) emissions, energy usage and waste and we are continuously working to improve our operational footprint.

Energy efficiency and emissions reductions

In 2016, we began implementing a continuous improvement program to focus on energy efficiency and reducing GHG emissions at global manufacturing locations.

Reduce emissions

As part of our strategy to reduce GHG emissions, we have undertaken the following projects at our Tyvek® manufacturing sites since 2016:

- Overhauled utility production equipment to switch to more sustainable energy resources, which facilitated significant GHG emission reductions

- Optimized heat recovery systems at our facilities, saving on energy and fuel

- Made improvements to heating, ventilation and air conditioning (HVAC) systems

- Retrofitted buildings with light-emitting diode (LED) lighting for greater emissions savings

Waste reduction

Our waste reduction efforts build on years of continuous improvement driven by the ISO 14001 certification process and by other compliance audits, as well as by our own internal standards and our vision of achieving zero waste—a goal we are very close to accomplishing.

We have implemented a 4R (Reduce, Reuse, Repurpose, Recycle) waste reduction program at both of our manufacturing sites and are partnering with other innovative companies to turn post-industrial waste from our manufacturing operations into valuable new products.

Water management

We withdraw and purchase water from various local sources and entities to conduct business. Some of that water is treated and returned to a local waterbody; some is rendered in our manufacturing processes or used for other purposes, such as employee health and hygiene.

As part of our ISO 14001 certification, we continuously monitor and strive to optimize our water consumption. To gain additional insights, we used the World Wildlife Fund (WWF) Water Risk Tool in 2020 to model water stress. The WWF tool helps us assess water risks using an expanded set of parameters, such as reputation and regulatory risk, that may affect business continuity in the future.

Working toward UN Sustainable

Development Goals

Consistent with the United Nations’ (UN) Sustainable Development Goals (SDGs) and in support of the DuPont 2030 Sustainability Goals, we are committed to delivering trusted product and program solutions for our customers and strategic value chain partners that will also help address climate change, drive toward a circular economy and help communities thrive.

To be successful in achieving these goals, we understand the importance of listening to the sustainability needs of our customers and partnering along the entire value chain.

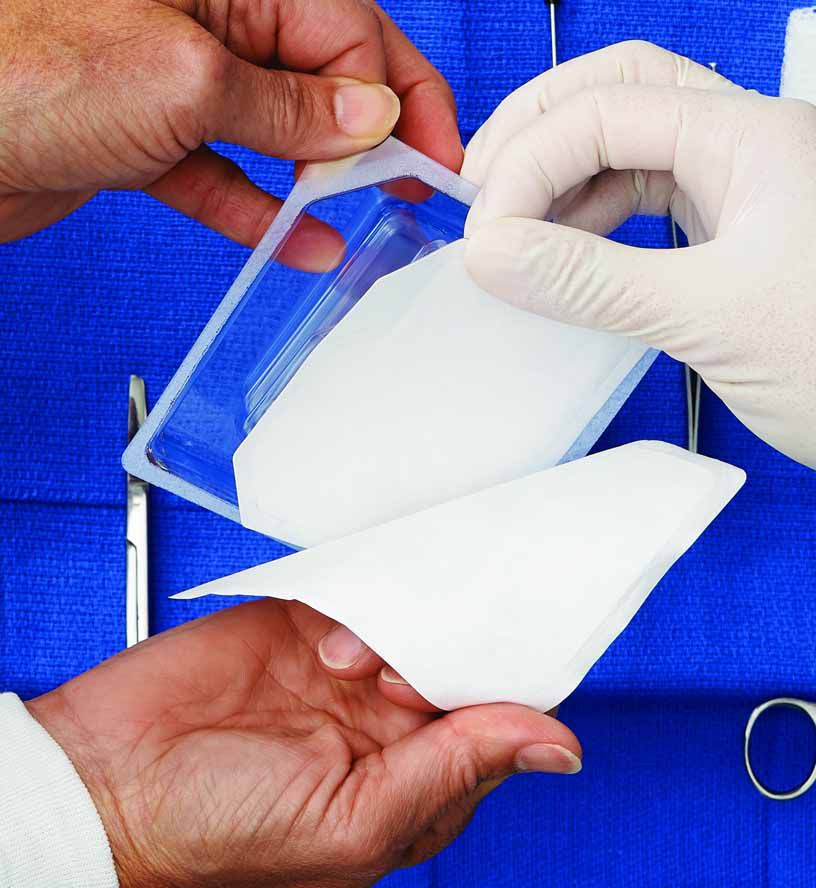

Sustainability benefits with Tyvek®

The unique properties and performance characteristics of Tyvek® that make it ideal for a wide variety of applications across diverse industries also make it a more sustainable solution.

<span class="fontsize24"><b><br>Low additives</b></span>

Tyvek® is made without plasticizers or restricted chemicals listed in European Directives, such as RoHS (Directive 2015/863/EU) or REACH Substances of Very High Concern (SVHC).

<span class="fontsize24"><b><br>Lightweight</b></span>

The superior strength-to-weight ratio of Tyvek® potentially can reduce energy use in transportation compared to heavier competitive products.

<span class="fontsize24"><b><br>Less waste</b></span>

Low material weights; high durability; and stable, functional performance result in less energy and resource consumption, as well as less material waste at the end of product life.

<span class="fontsize24"><b><br>Recyclability</b></span>

Tyvek® is made of high-density polyethylene (HDPE) and is recyclable.*

*Tyvek® is made of HDPE and products made of 100% Tyvek® material can be recycled at facilities that recycle flexible HDPE materials. Please check recycling facilities in your area to ensure they can recycle Tyvek®.

Contributing to a circular economy

In a resource-constrained world, we recognize the need to move away from linear “take-make-dispose” models as quickly as possible. We are integrating circular economy principles into our business models and collaborating across value chains to develop creative solutions that will reduce resource needs and reduce waste in all stages of a product’s lifecycle.

Recycling post-industrial waste

We established an on-site recycling facility alongside our Tyvek® manufacturing lines in Luxembourg. The facility uses a sophisticated shredder-feeder-extruder combination system that can process all types of Tyvek® production waste and then pelletize it for reuse.

This mechanical recycling system makes it easy and efficient to reprocess post-industrial waste back into high-density polyethylene (HDPE) granulates for reuse. As an example, the recycled HDPE granulates are used to produce plastic cores around which Tyvek® can be wound for storage and shipping.

We also have an ongoing relationship with Advanced Drainage Systems (ADS) to give Tyvek® production waste in Richmond, VA, a second life in highly engineered water management products.

Sustainability of Tyvek® applications

We have charted a course to help make sustainability a reality in the building industry over the next decade.

We’re working on protecting the planet with the same energy that drives our commitment to protecting people at work.

We’re proud of our role in helping people live longer and healthier, and we believe that advancing sustainability is an important extension of that role.

From general graphics, design and consumer products to packaging solutions, Tyvek® enables sustainable designs and provides recyclable, reusable and upcyclable solutions.

Commitment in action

Post-industrial waste from Tyvek® manufacturing is reprocessed into HDPE granulates that are used to produce plastic cores around which Tyvek® can be wound.

Fuel for the on-site cogeneration facility at Spruance was converted from coal to natural gas in order to produce steam and electricity more efficiently with fewer GHG emissions.

An ongoing relationship with ADS turns Tyvek® production waste into highly engineered drainage products.

Tyvek® is produced using renewable electricity in its operations. This milestone was achieved by purchasing renewable energy credits (RECs).