Tyvek® IsoClean® Doffing procedure for an ISO 5 aseptic cleanroom

-

Why Tyvek® IsoClean® ?

-

Industries

-

Fabric Solutions

-

Resources

For over 25 years Tyvek® IsoClean® garments have been an excellent choice for a variety of processes in cleanrooms and controlled environments because of the outstanding contamination control properties, fabric design and performance.

How To Validate Protective Cleanroom Garments?

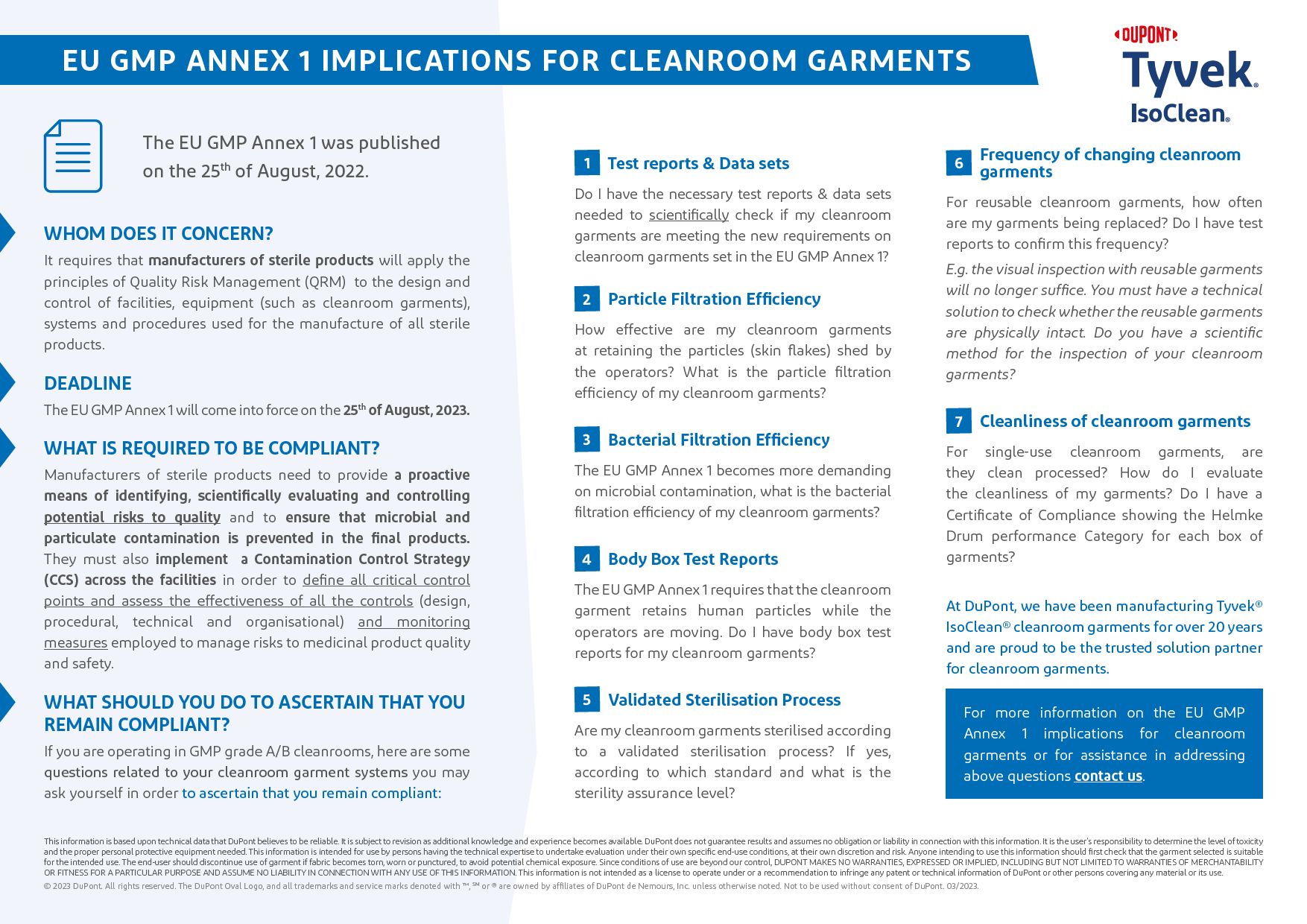

The revision of the EU GMP Annex 1 for the manufacturing of sterile products was published and will be effective on the 25th of August, 2023. This document aims to provide valuable information regarding this revision and its new requirements.

Manufacturers of sterile products need to provide a proactive means of identifying, scientifically evaluating and controlling potential risks to quality and to ensure that microbial and particulate contamination is prevented in the final products. They must also implement a Contamination Control Strategy (CCS) across the facilities to define all critical control points and assess the effectiveness of all the controls (design, procedural, technical, and organisational) and monitoring measures employed to manage risks to medicinal product quality and safety.

Why Tyvek® IsoClean®?

DuPont understands your need to do everything possible to improve productivity and reduce risk in your controlled environment. The DuPont Controlled Environments (CE) portfolio offers a comprehensive selection of single-use cleanroom apparel and accessories designed for use in various settings (cleanrooms grade A/B or ISO 4-5) that require high standards for particle and microbiological contamination control.

The highest performing garments in our product line are made from Tyvek®, which has been used to make high-quality cleanroom garments for more than 25 years. Tyvek® is made by DuPont with a proprietary flash-spinning process that creates continuous fibers of high-density polyethylene that are randomly distributed and non-directional.

Tyvek® IsoClean® cleanroom garments, designed for single use, offer meaningful advantages in today’s challenging cleanroom environments, including:

- Quality—single-use garments are not subjected to multiple cycles of wearing, laundering, and sterilization, so fabric barrier and strength are consistent and predictable.

- Flexibility—the DuPont single-use apparel program allows you to order only the quantities that you plan to use, which offers flexibility as your needs change.

- Cost control—single-use garments help eliminate budget uncertainties associated with garment repair, damage, and loss, helping you to better predict expenditures.

Tyvek® is inherently low linting and abrasion resistant

Tyvek® offers an ideal balance of protection, durability, and comfort.

Tyvek® acts as a breathable barrier against particles and bacteria.

Tyvek® repels aqueous liquids and liquid aerosols

Industries

Fabric solutions

Provides an inherent barrier to particles, microorganisms, and non-hazardous light liquid splash

Resources

The Tyvek® protective apparel recycling program offers the chance to divert garments away from landfills and give them a second life in products like containers, lumber pallets and park benches.

Videos

Articles & News

Single-use Tyvek® IsoClean® vs. Polyester reusable textile

Once again, DuPont scientists tested the barrier performance of a commercial polyester, reusable textile garment, typically used in European cleanrooms and Clean & Sterile Tyvek® IsoClean® garment model IC 183 B DS. The tests were performed on new garments and results do not include garment wear and multiplewashing and irradiation cycles.

The Expert Guide to Choosing and Wearing PPE

Protective coveralls are intended to protect against contamination from hazards in your working environment, ranging from liquid and solid chemicals, oils, non-toxic liquids, airborne substances, dusts and fibres.